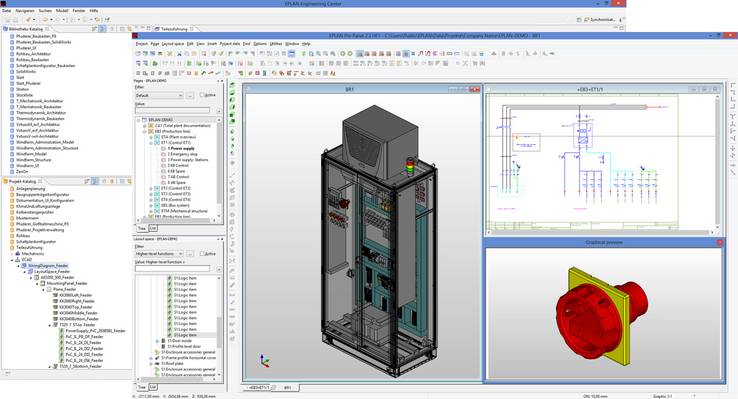

New coupling between EEC and EPLAN Pro Panel: Switchgear configured efficiently

Control cabinets and switchgears can now be automatically configured instead of being planned manually.

The new interaction between EEC and EPLAN Pro Panel ensures collaboration: control cabinets and switchgears can now be automatically configured instead of being planned manually. This saves time and sustainably ensures quality and reutilisation. EPLAN presents the solution at the 2014 Hannover Messe. Monheim, February 27, 2014 – Configuration instead of planning, this maxim has been a key factor for the continuously growing requirement of accelerating product development processes since introduction of the EPLAN Engineering Center (EEC). With the coupling of EEC and EPLAN Pro Panel Professional to form a integrated solution, the future-orientated technology of configuration is now also moving into control cabinet and switchgear manufacturing. The main advantage for users: configuration is based upon predefined rules and standards. All of the knowledge relating to components, modules, mechanical forms and electrical requirements are deposited in the system. This considerably improves the quality of documentation. The optional connection of EPLAN Pro Panel to the EEC is available with the new release of the EPLAN Engineering Center, which will be appearing at the Hannover Messe.

Knowledge anchored in the system

Companies that produce their own control cabinets can map the various components of control cabinet or switchgear manufacture in one modular system with the integrated solution of EEC and EPLAN Pro Panel. This modular system is the basis for the configuration of new, customer-specific control cabinets and switchgear. The options for reutilisation increase within the framework of configuration. In this way, users not only save time and money – the quality of documentation is also optimized due to standardization and quality control of the modules. If the modular system is filled with corresponding information, the mounting layout can be automatically generated in 3D. If required, the configuration can be expanded or adapted to suit the customer's needs. This also supports last-minute changes. The options for configuration in conjunction with the 3D software EPLAN Pro Panel unlocks new potential for use in technological engineering within the field of control cabinet and switchgear manufacturing.

Manufacturing, assembly, tender preparation

At the same time, the mounting layout is the basis for numerous other process steps in the manufacturing and assembly of the control cabinet solutions, such as e.g. virtual control cabinet wiring including length calculation of wires and cables. In this way, a continuous product development process is supported from the first concept draft via hardware and technological engineering right up to manufacture. In addition, manual manufacturing steps can then be completely automated by the creation of e.g. component and assembly lists, drilling templates and also manufacturing and assembly drawings. In addition, NC-machines for mechanical processing, automates for the wire- and terminal-assembly and robotics for automated device wiring are also supported.

The process chain in product development is thus significantly optimized. This also effects related disciplines such as e.g. the automated generation of quotations. In addition, engineering also benefits from this deep integration: Mechanical drawings, electrical schematics and PLC programs can be generated via EEC. Due to the automated generation of 3D mounting layouts, the efficient process of product development based on a mechatronic configuration is completed. Thus clear savings potentials can be achieved, especially for companies in the field of machine construction and also control cabinet and switchgear manufacturing. EPLAN Software & Service, March 2014