Process Industry

Your Process Plant Engineering Standard for All Sectors

One industry, many different sectors with various challenges and requirements. EPLAN engineering design software offers you data continuity, planning security and optimized processes for the oil and gas industry, pharmaceuticals, chemical industries, as well as water suppliers and the wastewater treatment sector among others. Here you can find an overview of the various areas and our solutions to help optimize your processes in an integrated way.

Oil and Gas

Three things are important to the planners and operators of process plant systems: plant system security, equipment loads and system availability. Operators of oil and gas plants can noticeably increase plant availability with efficient engineering because EPLAN engineering design software and solutions significantly optimize cooperation between engineering and operations. Based on integrated engineering software, your automation systems are compatible with operator objectives defined in the front-end engineering and development phase (FEED). Further, thanks to EPLAN’s integrated approach, you have a digital “as is” description of the plant systems, which ensures planning security in the event of operational modifications or load changes.

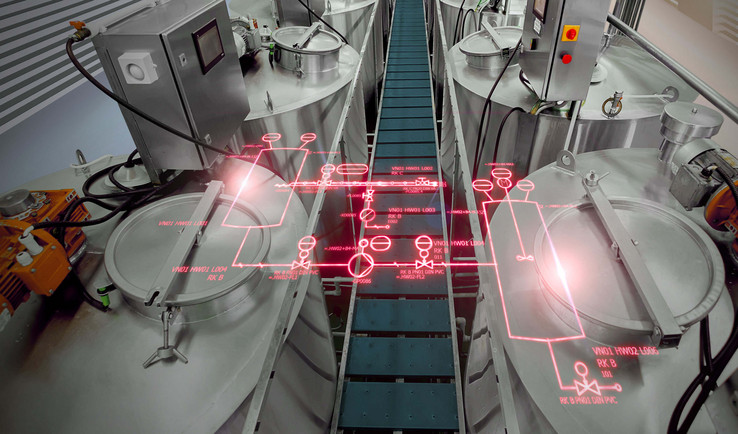

Pharmaceutical Industry

Digitalization is presenting new challenges for all industries. Megatrends such as globalization, an ageing society and personalized medicine also define the strategic fields of action for pharmaceutical companies. Research and production processes in the pharmaceutical industry are complex. Every facility has numerous systems and components that must run smoothly to ensure trouble-free production, reduce costs and shorten the time to market. In order to keep up with current developments, flexible structures and integrated processes are needed to allow pharmaceutical companies to quickly react to changing requirements along their entire product life cycles. This is exactly where you can rely on EPLAN as a strong partner.

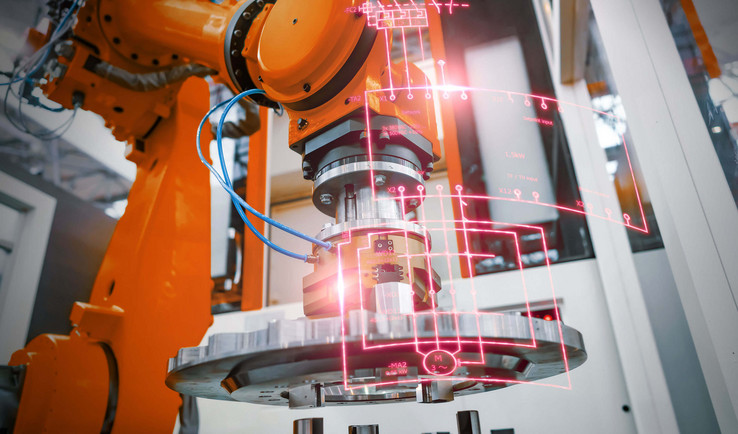

Chemical Industry

The current trend of a circular economy is challenging chemical companies to develop products that are recyclable or that support recycling concepts. Understanding the needs of customers along the entire value chain, developing appropriate solutions and using the generated added value for profitable growth are all crucial for ensuring long-term success in the chemical industry. Digital innovations are extremely helpful, such as showing essential links of the value chain using a digital twin. EPLAN delivers integrated system solutions with its affiliates like Rittal.

Water and Wastewater Management

The world’s limited resources make expert and sustainable water and wastewater management systems an absolute necessity. Aside from environmental aspects, this industry must master numerous technical and economic challenges. Efficient engineering plays an important role in secure water supplies and wastewater management: data continuity and a high degree of standardization simplify the introduction of new technologies. Further, it also makes it possible to achieve uninterrupted plant system operations and to coordinate teams throughout a company.

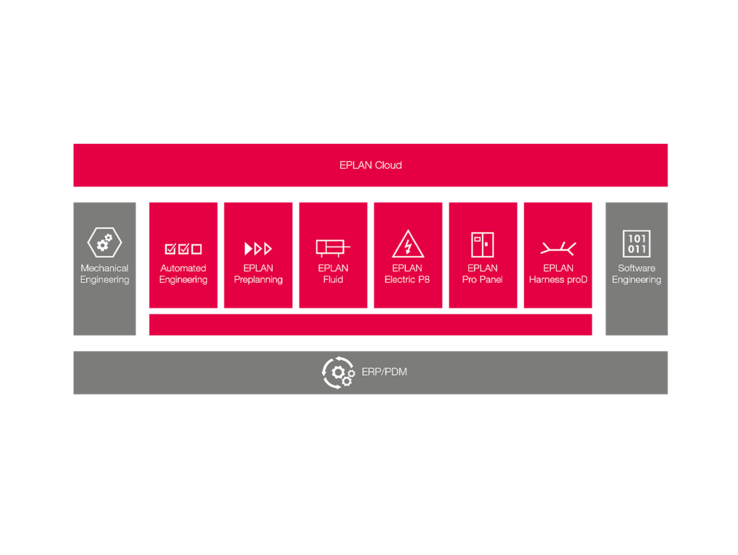

Our Solutions for the Process Industry

Discover our integrated solutions that match your specific areas of application.

EPLAN in Practice

Find out how companies from a wide variety of industrial sectors are using our solutions to meet current technical development challenges and improve their competitiveness.

We're happy to help!

Would you like to find out more about our solutions or services? Then contact us – we’re here for you!