EPLAN ePULSE: Increasing quality at the product and process levels

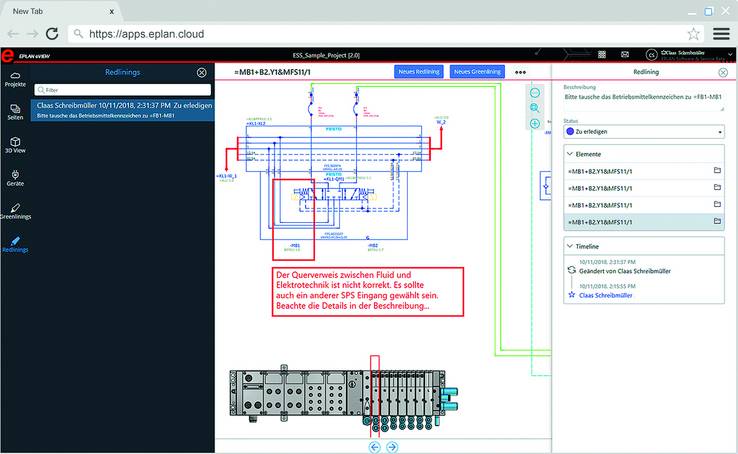

Solutions provider EPLAN has already been offering cloud-based systems for a while. EPLAN Data Portal is established worldwide as a manufacturer library for downloading device data. Since early 2019, EPLAN eVIEW has expanded the range of solutions with which ECAD projects can be viewed, verified and commented on using a redlining workflow. With EPLAN ePULSE, the company’s course towards agile cloud development is now being systematically continued in dialogue with customers and partners.

The new EPLAN ePULSE cloud strategy

Solutions provider EPLAN has already been offering cloud-based systems for a while. EPLAN Data Portal is established worldwide as a manufacturer library for downloading device data. Since early 2019, EPLAN eVIEW has expanded the range of solutions with which ECAD projects can be viewed, verified and commented on using a redlining workflow. With EPLAN ePULSE, the company’s course towards agile cloud development is now being systematically continued in dialogue with customers and partners. Monheim, Germany, 27 February 2019: EPLAN ePULSE, the company’s newest solution offering, is the foundation for a complete network of cloud-based systems that bring together data and projects, disciplines and engineers around the world. Using their internet browsers, users get access to applications that enhance the existing EPLAN Platform product world with new functions along the data-driven value chain. The open design of EPLAN ePULSE includes future plans to ensure availability to a variety of data formats and interfaces to systems from other providers.

Connection in the supply chain

“We’re using agile development methods for our cloud offerings and are keeping a close eye on our customers’ needs,” says Sebastian Seitz, Chief Executive Officer at EPLAN and Cideon. “EPLAN ePULSE serves as the connection within the supply chain between end custom-ers, machine and plant suppliers, and component manufacturers in industrial production.” The project data stored in EPLAN ePULSE is both the system description for a company’s in-house manufacturing and customer documentation for all aspects of the digital twin relevant to automation. “In the era of digitization, this allows our customers to rely 100 per cent on digital data,” Seitz explains. To this end, EPLAN has created a new unit that provides fresh impetus in the style of today’s think tanks. Experiments are carried out here and discussed with customers and partners. Not every idea will see the light of day, but creative thinking is more than welcomed and encouraged.

An overview of EPLAN’s cloud-based systems

- With EPLAN eVIEW, engineering projects gener-ated in the EPLAN Platform will be directly ac-cessible in the cloud. This means that project data can be viewed at any time from anywhere. A red-lining function lets employees on the shop floor or in maintenance add their suggestions for changes into the schematics.

- EPLAN Data Portal offers web-based access to high-quality product catalogues of numerous component manufacturers. All the solutions an-chored in the EPLAN Platform have equal access to this web service. The easy drag-and-drop transfer of components into the EPLAN docu-mentation reduces the time and effort needed for engineering design and increases the quality of machine and plant documentation.

- With the cloud version of EPLAN Cogineer gen-erating schematics from a template library with just a few clicks will soon be possible directly in a browser. The new expanded version, EPLAN Co-gineer Advanced, offers additional functions: the importing of configuration variables and value sets and the easy re-use of subfunctions all help make creating models even easier.

Background

Cloud solutions are an effective tool for advancing data and process standardization. In engineering, this goes hand-in-hand with new chances for process optimization and increased quality at the product and process levels. Ultimately all participants will be working from the same uniform database – with the option to expand access across the supply chain. The cloud as a central location for exchanging relevant engineering data provides fast access, making this gateway to high-quality digital data from any location extraordinarily easy to use. EPLAN ePULSE allows companies to maintain their competitive-ness in today’s world, with a clear potential for continued success over the long term.